Are ORFS Adapters Compatible with Various Hydraulic Fluids and Temperatures?

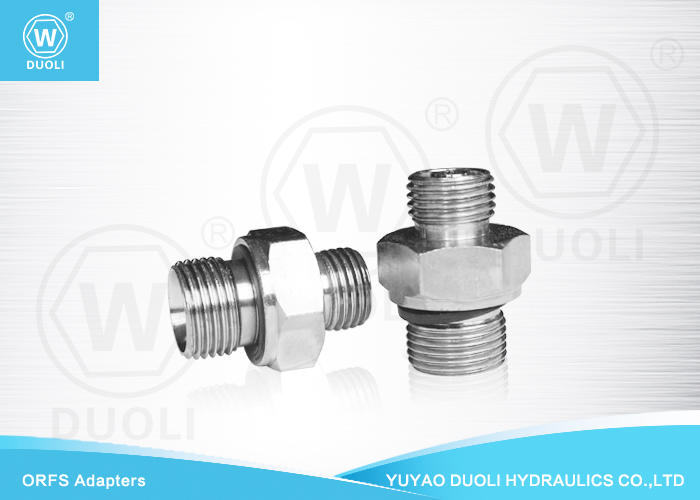

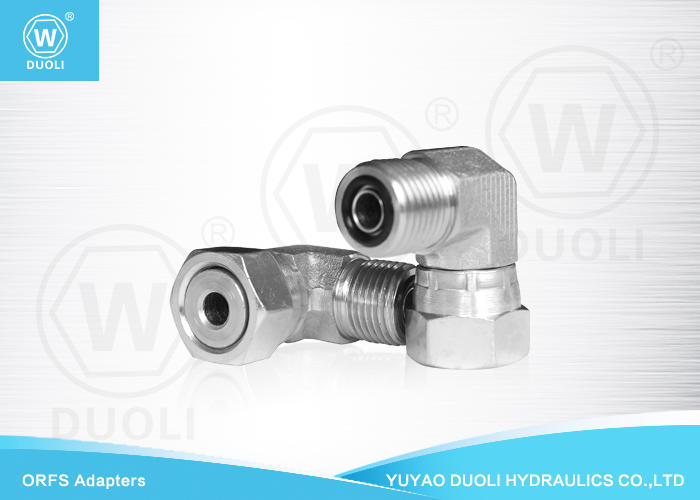

ORFS (O-Ring Face Seal) adapters play a crucial role in hydraulic systems, facilitating secure and leak-free connections between components. One common concern when selecting hydraulic components is their compatibility with various hydraulic fluids and operating temperatures. In this regard, ORFS adapters offer several advantages and considerations.

First and foremost, ORFS adapters are designed with materials that exhibit excellent compatibility with a wide range of hydraulic fluids commonly used in industrial applications. These fluids may include hydraulic oils, synthetic fluids, water-based fluids, and even certain aggressive fluids used in specialized applications. The materials typically used in ORFS adapters, such as steel, stainless steel, or brass, are chosen for their corrosion resistance and durability, ensuring long-term performance and reliability in diverse hydraulic environments.

Additionally, the O-ring seals employed in

ORFS adapters are selected based on their compatibility with different hydraulic fluids. Common seal materials include Buna-N (Nitrile), Viton, and EPDM, each offering varying degrees of chemical resistance and temperature tolerance. These seals form a tight, reliable seal between the adapter and mating components, preventing leaks and ensuring the integrity of the hydraulic system.

One of the significant advantages of ORFS adapters in terms of fluid compatibility is their ability to maintain sealing effectiveness across a broad temperature range. Hydraulic systems often operate in environments where temperatures can fluctuate significantly, from extreme cold to high heat. ORFS adapters, when paired with appropriate O-ring seals, can withstand these temperature variations without compromising sealing performance. This versatility makes ORFS adapters suitable for use in a wide range of applications and environments, including automotive, aerospace, construction, agriculture, and industrial machinery.

The design of ORFS connections contributes to their compatibility with various hydraulic fluids and temperatures. The flat mating surface of ORFS adapters ensures uniform sealing pressure around the O-ring, minimizing the risk of leaks even under challenging operating conditions. This design feature also enhances the adapters' resistance to vibration and mechanical stress, further enhancing their reliability in demanding applications.

When selecting ORFS adapters for a specific hydraulic system, it's essential to consider the compatibility of both the adapter materials and O-ring seals with the intended fluid and operating temperature range. Manufacturers typically provide specifications and compatibility charts to assist in this process, guiding users in selecting the most suitable components for their applications.

ORFS adapters offer excellent compatibility with a wide range of hydraulic fluids and operating temperatures, thanks to their robust materials, high-quality O-ring seals, and thoughtful design. By choosing

ORFS adapters, hydraulic system designers and operators can ensure leak-free connections and reliable performance in diverse industrial settings, contributing to overall system efficiency and safety.